Things you may want to know

02 Dec

20 Comment(s)

80099 View(s)

Hardwood flooring is a beautiful and unique product of nature, which is characterized by distinctive variations in grain and colors. These natural variations in color and grain are not flaws but are a part of the natural beauty and uniqueness of hardwood flooring. These inherent variations should be expected and serve to enhance the natural beauty and enduring charm. Our floorings are manufactured in accordance with accepted industry standards, which permit a defect tolerance not to exceed 5%. The defects may be of a manufacturing or natural type.

Before we head to the installation... Things you need to know...

Job site Inspection& Acclimation

- This type of real wood flooring

can be installed below, equal or above

ground level. Do not install

in a bathroom.

- In a new construction, hardwood flooring should be one of the last items installed. All work involving water or moisture (plumbing, acoustical ceilings, dry wall taping, etc.) should be completed prior to wood flooring being installed. Heating and air systems should be fully operating maintaining a consistent room temperature at 16°C to 27°C (60-80° F) and a constant relative humidity of 40% to 55%.

- Flooring

should not be delivered until the building has been closed in and cement work,

plastering, painting and other materials are completely dry. Concrete and plaster should be cured

and at least 60 days old.

Check basements and under-floor crawl space to be sure that they are dry and

well ventilated to avoid damage caused by moisture.

- Handle

with care. Do not stand on ends. Store our flooring in a dry place being sure to provide

at least a four-inch air space under and around cartons.

- Do not store

directly on concrete or near outside

walls. Cartons should

be placed in the installation

area.

- The humidity level of the house must be maintained between 40 % and 55 % all year long. Wood is a living product which reacts to humidity level variations. During summer, where the humidity level is at its highest point, the wood has a natural expansion and absorbs the humidity, these variations must be dealt with adequate dehumidification. As for winter, when the heating system is working, the humidity level is lower. It is then recommended to use a humidifier to minimise the extreme effects of shrinkage.

Subfloor conditions

- Clean- Scraped or sanded, swept, free of wax, grease, paint, oil and other debris.

- Horizontal/ Flat- Maximum tolerance of 5mm over 3m(3/16'' over 10') or 3mm over 2m(1/8'' over6')

- Sand high areas or joints.

If the floor is glued,

fill the fill low areas with a latex additive

cement surfacing product with a minimum resistance to compression of 20

000 kPa.

- Concrete

Slabs (regardless of existing floor covering): Use an approved calibrated

concrete Moisture Meter as a preliminary measurement for moisture. Concrete

subfloors must be finished at least 30 days before performing a test. Acceptable verification methods: Perform a polyfilm

test. Tape down 2’ x 2’ polyfilm

squares (a clear garbage bag or plastic drop cloth will do) in several places

on the floor. Wait 24-48 hours, and then check for the appearance of condensation

on the inside of the bag or plastic for a darkening on the concrete subfloor.

Either occurrence signals the likely presence of excess moisture, which needs

other measures with the concrete moisture meter Tramex. The measure must not

climb over 4,5 on the superior graduation. The floor can be glued directly on

concrete with a compression resistance of at least 20 000 kPa (3 000 lb/in2).

- Wood Substrates: Test the moisture of the wood substrate using a calibrated moisture meter approved for testing wood moisture according to the meter manufacturer. The reading should not exceed 12%, or read more than a 4% difference than moisture content of products being installed.

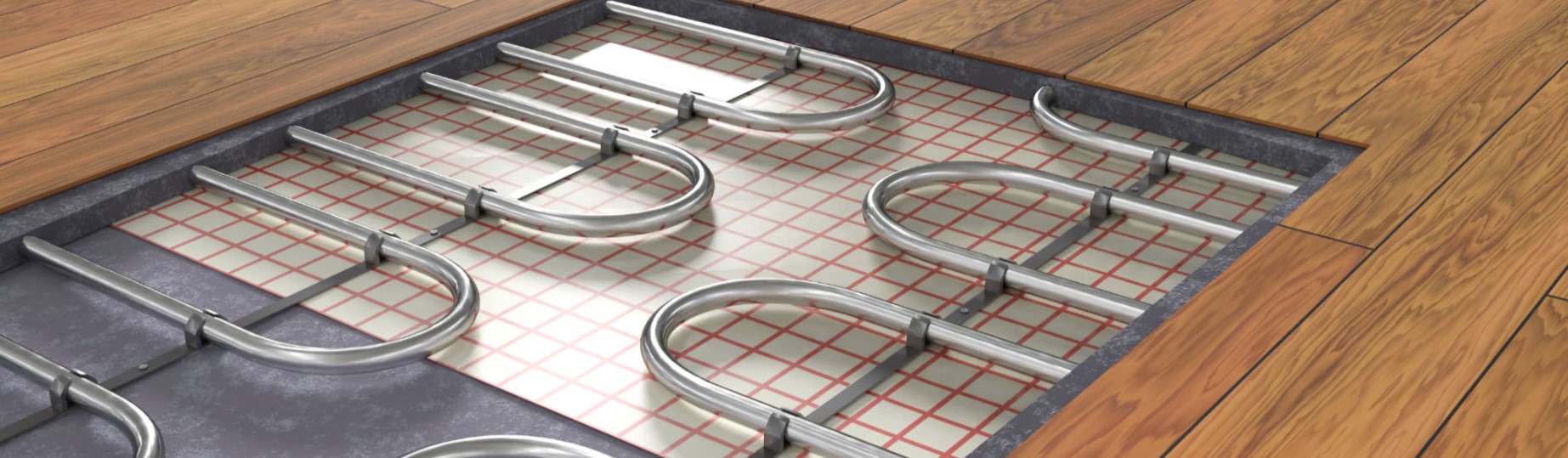

Radiant Subfloor heating

NOTE: Always

make sure that the selected

product is recommended for this type of installation. Some species are not compatible and cannot be installed on this

type of subfloor; Jatoba, Maple, Kempas, Ironwood, Ipé, Asian Mahogany are some

species that are not suitable for Radiant heating. Please ensure that the

species you have chosen is suitable.

- The heating system must be functional and working for at least 7 days prior to the floor installation.

- Stop the heating and let the floor cool down to ambient temperature for 3 or 4 hours before

starting the floor installation.

- Immediately start the radiant

heating system after the installation. The temperature of the finished surface cannot go over 27 °C (80

°F) at all times for the duration of the flooring’s life span.

- Radiant

heating systems usually procure a dry heat which can lower the ambient humidity

level. It could be necessary to use a humidifier to maintain a recommended level

of 40 % to 55 % and prevent

any damage to the floor.

- Flooring

installed on a radiant heating system must be glued at each end, in order to

reduce the shrinkage in length.

Apply a layer of recommended wood glue on the grooved

side before inserting the strip.

- The heating system must be functional and working for at least 7 days prior to the floor installation.

- Stop the heating and let the floor cool down to ambient temperature for 3 or 4 hours before

starting the floor installation.

%20(1000%20×%20700%20px)%20(1000%20×%20650%20px)%20(1000%20×%20670%20px)-700x500w.png)

1586 Comment(s)

I gotta favorite this internet site it seems handy .

Thank you for another great article. Where else could anyone get that kind of information in such a perfect way of writing? I have a presentation next week, and I am on the look for such information.

I observe there is plenty of spam on this weblog. Do you need assist cleaning them up? I might help among classes!

Thank you for another great article. Where else could anyone get that kind of information in such a perfect way of writing? I have a presentation next week, and I am on the look for such information.

Your article has piqued a lot of positive interest. I can see why since you have done such a good job of making it interesting.

Promptly the internet site could possibly irrefutably receive credited extremely connected with placing people, to its conscientious articles and reviews or maybe vital opinions.

I enjoy the variety of blogposts, I actually certainly favored, I like more knowledge about them, considering it is rather excellent., All the best designed for revealing.

i am for the first time here. I found this board and I in finding It truly helpful & it helped me out a lot. I hope to present something back and help others such as you helped me.

Wow, What an Outstanding post. I found this too much informatics. It is what I was seeking for. I would like to recommend you that please keep sharing such type of info.If possible, Thanks.

What a lovely blog. I will certainly be back. Please keep writing!

Hi there! This is my first visit to your blog! We are a team of volunteers and starting a new project in a community in the same niche. Your blog provided us beneficial information to work on. You have done a extraordinary job!

I am unable to read articles online very often, but I’m glad I did today. This is very well written and your points are well-expressed. Please, don’t ever stop writing.

Sorry for that huge review, but I am actually loving the new Zune, and hope this, along with the outstanding reviews some other people have written, will help you determine if it’s the appropriate selection for you.

Your writing style is engaging and the content is top-notch. Looking forward to more posts!

Attractive section of content. I just stumbled upon your blog and in accession capital to assert that I get in fact enjoyed account your weblog posts. Anyway I will be subscribing to your augment and even I achievement you access consistently rapidly.

Tech Supply Co. is one of Canada’s most reliable B2B platforms offering a wide range of electronics including printer ink and toner. Buy your office essentials online at Tech Supply Co.

Great post! Your writing is clear, and the content is very helpful.

Wow, What an Outstanding post. I found this too much informatics. It is what I was seeking for. I would like to recommend you that please keep sharing such type of info.If possible, Thanks.

usually, i buy my craft supplies on the internet because of the cheaper price and countless options,

Very efficiently written information. It will be beneficial to anybody who utilizes it, including me. Keep up the good work. For sure i will check out more posts. This site seems to get a good amount of visitors.

Leave a Comment